9S

Mechanical

The 9S mechanical movement was introduced in 1998. Grand Seiko 9S mechanical movements and watches are produced at the Grand Seiko Studio Shizukuishi, one of the world’s leading watch manufacturing facilities, tucked away in a quiet, forested part of Iwate Prefecture.

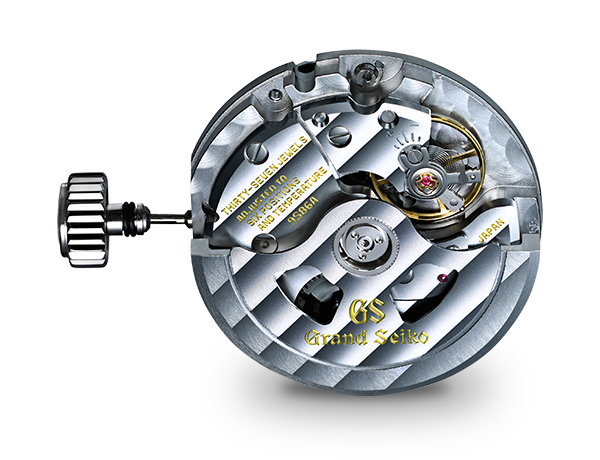

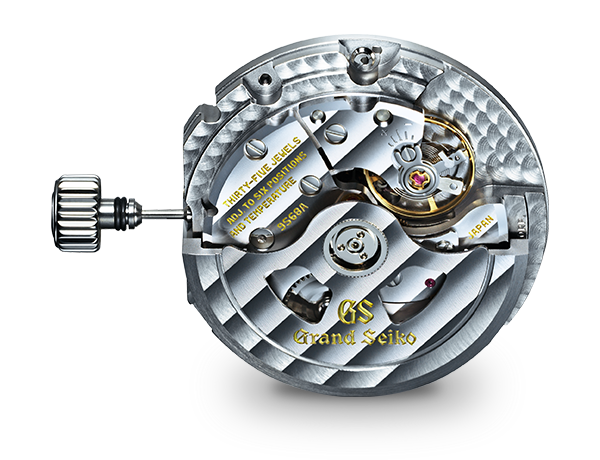

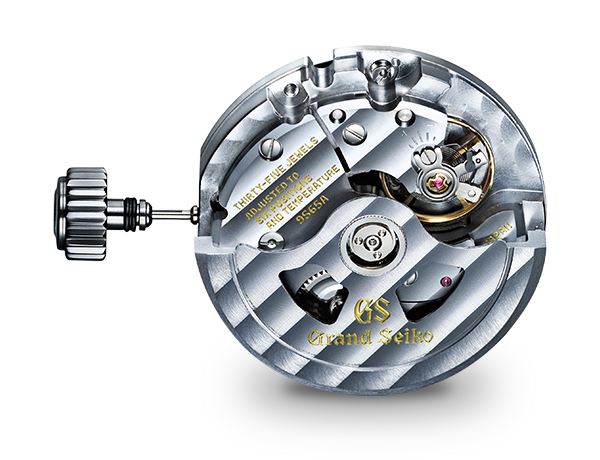

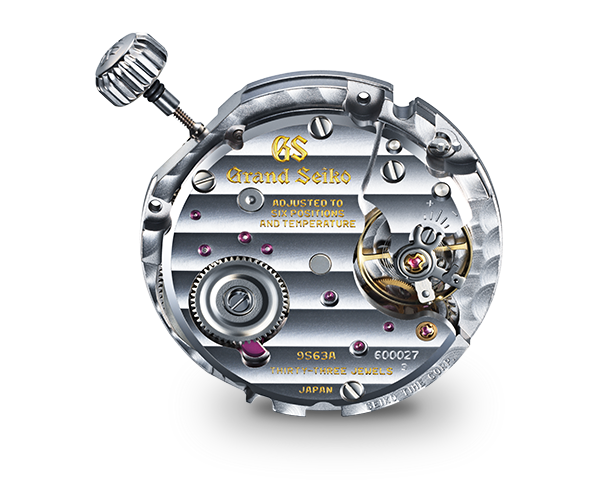

The movement is as beautifully finished as it is efficient. In some 9S movements, delicate stripe finishing is inspired by the Shizukuishi Rover, which runs near the studio.

Grand Seiko Studio Shizukuishi

As a true manufacture, Grand Seiko combines the latest technology with its long experience in handcraftsmanship to raise the art of watchmaking to new heights.

With hundreds of individual components, mechanical watches must exhibit a near-perfect consistency in the detail of these parts to ensure the precision of the movement. High technology plays an important part in ensuring the level of performance required by the Grand Seiko Standard. For example, Grand Seiko employs Micro-Electro-Mechanical Systems (MEMS) in the manufacturing of its escapements, bringing to its mechanical watches a technology that was born in the development of semiconductor manufacturing. Perfect components alone, however, cannot deliver the level of precision for which Grand Seiko is renowned. The task of assembling each Grand Seiko watch is carried out by craftspeople who have honed their craft to such an extent that they can adjust parts by hand to tolerances of one hundredth of a millimeter. It is the combination of high technology and this skilled craftsmanship that ensures the precision of each 9S mechanical movement.

Mechanism

Mechanical watches have an escapement, a self-contained device that draws its power from the motive force of an unwinding mainspring and uses this power to regulate the speed at which the spring unwinds. This system has remained largely unchanged since moving hands were first used to tell time.

A wound-up mainspring exerts force to turn gears at a set speed as it unwinds. The precision of the system as a whole is dictated by this speed and the escapement mechanism, comprising the balance, pallet fork, and escape wheel.

If the force from the mainspring were transmitted directly to the hands, they would rotate at an uncontrollable speed, making accurate timekeeping impossible.

To prevent this, the escapement regulates the rotation of the gears to ensure precise timekeeping.

Through the escape wheel and pallet fork, the power of the mainspring is transmitted to the balance, which is equipped with a hairspring. This hairspring expands and contracts, allowing the balance to oscillate back and forth.

This regular oscillation is transferred to the pallet fork, which controls the rotation of the escape wheel at a constant rate.

In this way, the mainspring unwinds gradually and evenly over a long period of time, and this consistent motion is transmitted through the gear train to drive the hour, minute, and seconds hands with precision.

Adjusting the hairspring – the key to precise timekeeping

The hairspring is the critical component at the heart of a mechanical watch as it governs its precision.

Elegantly coiled hairsprings are akin to living creatures, with individual characters all their own. Grand Seiko’s craftspeople can identify and work with this variation, inserting pincers into the spaces within the coil to make adjustments by hand with a precision of one hundredth of a millimeter.

The balance wheel – a pillar of precision

The balance wheel is the component that ensures a consistent beat. This part is so critical to the overall precision of every Grand Seiko watch that its weight is adjusted to tolerances of one microgram.

Because it is so sensitive, even the slightest temperature change can cause it to expand or contract, potentially leading to distortions in shape.

The 9S mechanical movement minimizes the effects of temperature on the balance wheel and preserves overall precision by incorporating an additional arm over the usual two or three.

While this attention to detail increases the level of work required to manufacture the balance wheel, it is vital in maintaining the highest possible levels of precision. Grand Seiko is committed to doing everything possible to ensure the perfect function of this all-important wheel.

Polished by hand

Power must flow between the gears with only a minimal loss of energy for the watch to perform perfectly over time.

To ensure the efficient transfer of the mainspring’s power, Grand Seiko’s craftspeople polish the pinions one by one.

The painstaking polishing of every gear tooth ensures that friction is minimized and that the longevity of every component is extended.

MEMS technology for high-precision parts

Micro-Electro-Mechanical Systems (MEMS) technology is used to fabricate precision parts for Caliber 9S. MEMS, a highly advanced semiconductor manufacturing technology, makes it possible to produce lightweight parts with extreme precision and tolerances of one millionth of a millimeter.

Quality control for the high standard of accuracy

The accuracy of a mechanical watch during daily wear can vary depending on environmental factors. To demonstrate the superior performance of Grand Seiko’s mechanical watches, Grand Seiko has established its own precision standard known as the “Grand Seiko Standard.”

Each 9S mechanical movement is assessed against a unique and rigorous set of standards. The movement is tested in six different positions and at three different temperatures, and its daily variations must fit within very strict tolerance rates in order to pass the test of the Grand Seiko Standard.

* The images used on this page feature Caliber 9SA5. Please note that the structure of the movement and the specifications of its components may vary depending on the caliber.

9S Mechanical Models

9S Mechanical Movement

Movement Comparison

| Movement | Mean daily rate*1 | Normal usage accuracy | Power reserve | Vibrations | Number of jewels | Features |

|---|---|---|---|---|---|---|

| Manual-winding Mechanical Hi-Beat 36000 80 Hours Caliber 9SA4 (Manual winding mechanical) |

+5 to -3 seconds per day | +8 to -1 seconds per day | Approximately 80 hours | 36,000 vibrations per hour (10 beats per second) | 47 jewels | · Dual Impulse Escapement

· Twin barrels · Power reserve indicator |

| Hi-Beat 36000 3-Day Chronograph Caliber 9SC5 (Automatic with manual winding) |

+5 to -3 seconds per day | +8 to -1 seconds per day | Approximately 72 hours | 36,000 vibrations per hour (10 beats per second) | 60 jewels | -Chronograph

-Dual Impulse Escapement -Twin barrels |

| Hi-Beat 36000 80 Hours Caliber 9SA5 (Automatic with manual winding ) |

+5 to -3 seconds per day | +8 to -1 seconds per day | Approximately 80 hours | 36,000 vibrations per hour (10 beats per second) | 47 jewels | -Dual Impulse Escapement

-Twin barrels -Instant date change mechanism |

| Mechanical Hi-Beat 36000 GMT Caliber 9S86 (Automatic with manual winding mechanism) |

+5 to -3 seconds per day | +8 to -1 seconds per day | Approximately 55 hours | 36,000 vibrations per hour (10 beats per second) | 37 jewels | -Dual time function with 24-hour hand

-Quick correction function of time difference adjusting to a calendar |

| Mechanical Hi-Beat 36000 Caliber 9S85 (Automatic with manual winding mechanism) |

+5 to -3 seconds per day | +8 to -1 seconds per day | Approximately 55 hours | 36,000 vibrations per hour (10 beats per second) | 37 jewels | -Date display |

| Automatic 3-Day Power Reserve Caliber 9S68 (Automatic with manual winding mechanism) |

+5 to -3 seconds per day | +10 to -1 seconds per day | Approximately 72 hours | 28,800 vibrations per hour (8 beats per second) | 35 jewels | -Date display |

| Automatic 3-Day Power Reserve GMT Caliber 9S66 (Automatic with manual winding mechanism) |

+5 to -3 seconds per day | +10 to -1 seconds per day | Approximately 72 hours | 28,800 vibrations per hour (8 beats per second) | 35 jewels | -Dual time function with 24-hour hand

-Quick correction function of time difference adjusting to a calendar |

| Automatic 3-Day Power Reserve Caliber 9S65 (Automatic with manual winding mechanism) |

+5 to -3 seconds per day | +10 to -1 seconds per day | Approximately 72 hours | 28,800 vibrations per hour (8 beats per second) | 35 jewels | -Date display |

| Manual-winding Caliber 9S64 (Manual winding mechanical ) |

+5 to -3 seconds per day | +10 to -1 seconds per day | Approximately 72 hours | 28,800 vibrations per hour (8 beats per second) | 24 jewels | - |

| Manual-winding with a Small Seconds Hand Caliber 9S63 (Manual winding mechanical ) |

+5 to -3 seconds per day | +10 to -1 seconds per day | Approximately 72 hours | 28,800 vibrations per hour (8 beats per second) | 33 jewels | -Power reserve indicator

-Small seconds hand |

| Small Size Automatic Caliber 9S27 (Automatic with manual winding mechanism) |

+8 to -3 seconds per day | +10 to -5 seconds per day | Approximately 50 hours | 28,800 vibrations per hour (8 beats per second) | 35 jewels | -Date display |

- Mean daily rate is a mean value of daily rates in a condition where the movement before assembly in a case is measured in six positions in a fixed manner under artificially controlled environment for 12 days.