9R

Spring Drive

The 9R Spring Drive movement took over 20 years from its initial conception to complete development. Only after it had achieved exceptional performance with automatic winding and 72 hours of power reserve was it deemed worthy of the Grand Seiko name and introduced in 2004. This special movement is manufactured and hand-assembled at the Shinshu Watch Studio located in Shiojiri, Nagano Prefecture.

Powered by a traditional mainspring yet controlled by a quartz oscillator and integrated circuit (IC), Spring Drive achieves a level of accuracy unimaginable in purely mechanical watches.

The seconds hand moves in a uniquely smooth and silent glide motion – expressing the natural flow of time, unlike the ticking of quartz or the beat of traditional mechanical watches.

Mechanism

The system that controls the accuracy of 9R Spring Drive is Grand Seiko’s uniquely innovative Tri-Synchro Regulator, a mechanism that uses power from a mainspring – like a traditional mechanical watch – to achieve high precision made possible by a quartz oscillator and integrated circuit (IC).

As the mainspring unwinds, it drives a rotor, known as the “glide wheel” in a Spring Drive watch. The glide wheel interacts with a stator – a coil-wound component – to generate a small amount of electricity. This energy powers the quartz oscillator and IC. Once activated, the quartz oscillator emits an extremely precise signal of 32,768 Hz, just like in a quartz watch.

The IC compares this reference signal with the actual rotation speed of the glide wheel. If it is spinning too quickly, the IC applies an electromagnetic brake to slow the glide wheel down, ensuring a steady eight rotations per second. The precision braking of the glide wheel is transmitted back through the gear train to the hands, resulting in the accuracy and signature glide motion of the seconds hand.

By harmonizing three types of energy – mechanical, electrical, and electromagnetic – the Tri-Synchro Regulator represents a groundbreaking achievement that seamlessly blends the traditions of mechanical watchmaking with the advanced accuracy of quartz technology.

Tri-Synchro Regulator

1. MECHANICAL POWER

Generating electrical power from the unwinding mainspring

Spring Drive uses a system identical to that of a pedal-powered bicycle light to generate electrical power. A rotor connected to the end of the gear train acts together with a stator wound with wire to generate power. In a Spring Drive watch, the rotor, or “glide wheel,” makes eight full revolutions every second, generating a slight electric current.

2. ELECTRICAL POWER

Transmitting a precise signal from a quartz crystal oscillator

The electrical power generated by the glide wheel is used to activate a quartz oscillator and an IC. The quartz oscillator vibrates at exactly 32,768 Hz, and this is transmitted as a precise reference signal to the IC.

3. ELECTROMAGNETIC POWER

Applying the brake to control speed

The IC compares the reference signal from the quartz oscillator with the revolution speed of the glide wheel, and intermittently applies a magnetic brake when it detects that the glide wheel is operating too fast. This regulation of the glide wheel is transmitted to the gear train, ensuring that the hands move with precision.

The interaction of these three energy sources results in the perfectly smooth and accurate movement of the seconds hand.

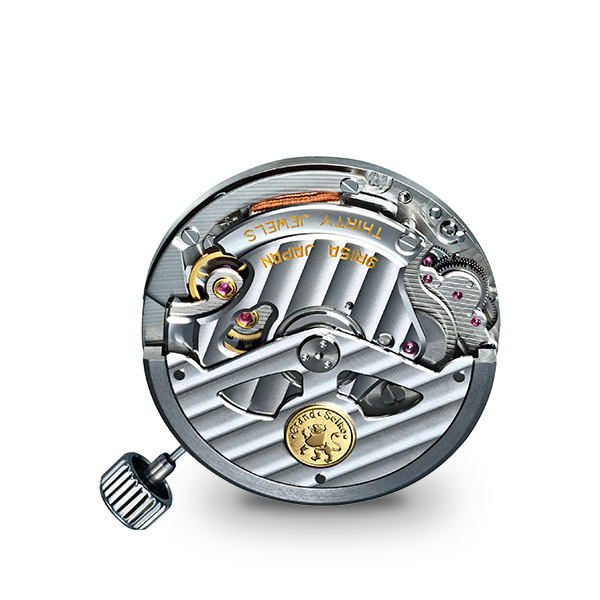

* Images shown on this page are of the Spring Drive Caliber 9RB2. Movement construction and component specifications may differ depending on the specific caliber.

Master craftsmanship in assembly and adjustment

Spring Drive combines the best elements of both mechanical and electronic watches. The number of components exceeds two hundred, and the assembly process involves carefully applying the appropriate type and amount of oil to numerous minute areas. This procedure, which directly affects the watch's performance and durability, requires a high level of skill and concentration.

Design plans are based on tolerances down to the one hundredth of a millimeter. The final adjustments and refinement of the components are completed by hand, because no machine can match the skills of the watchmakers whose superior craft gives rise to the extreme precision of Spring Drive.

Longer and thicker hands

While quartz movements benefit from high precision, they commonly lack the torque to move thicker hands. In contrast, mechanical movements enjoy higher torque, allowing for larger hands that reach right to the edge of the dial, but cannot match the level of precision of their quartz counterparts. Spring Drive combines the precision of a quartz watch with the torque of a mechanical watch, to allow both the long hands and the high precision that Grand Seiko demands.

The Spring Drive 9R86 chronograph movement

With mechanical chronographs, the power reserve generally decreases when using the chronograph function, and the measurement accuracy becomes inconsistent as the torque decreases. After a painstaking examination of the gear trains and even tooth designs, the Spring Driven Chronograph development team sought to ensure sufficient torque for power generation by minimizing the mechanical load. This resulted in a power reserve of 72 hours even under increased load during chronograph operation – a groundbreaking achievement for a spring-driven chronograph. What's particularly remarkable is that the Spring Drive Chronograph maintains an impressive accuracy of ±15 seconds per month (±1 second per day) even during chronograph operation.

9R Spring Drive Models

9R Spring Drive Movement

Movement Comparison

| Movement | Accuracy | Power reserve | Number of jewels | Features |

|---|---|---|---|---|

| Spring Drive U.F.A. Caliber 9RB2 (Automatic with manual winding) |

±20 seconds per year (±3 second per month) | Approximately 72 hours (3 days) | 34 jewels | -Offset Magic Lever

-One-piece Center Bridge -Power-reserve indicator -Date display |

| Spring Drive 5 Days Caliber 9RA2 (Automatic with manual winding) |

±10 seconds per month (±0.5 second per day) | Approximately 120 hours (5 days) | 38 jewels | -Offset Magic Lever

-Dual-size Barrels -One-piece Center Bridge -Power reserve indicator |

| Spring Drive 5 Days Caliber 9RA5 (Automatic with manual winding) |

±10 seconds per month (±0.5 second per day) | Approximately 120 hours (5 days) | 38 jewels | -Offset Magic Lever

-Dual-size Barrels -One-piece Center Bridge -Power reserve indicator |

| Manual-winding 8-Day Power Reserve Spring Drive Caliber 9R01 (Manual winding) |

±10 seconds per month (±0.5 second per day) | Approximately 192 hours | 56 jewels | -Power reserve indicator

-Quick correction function of time difference |

| Manual-winding Spring Drive Caliber 9R02 (Manual winding) |

±15 seconds per month (±1 second per day) | Approximately 84 hours | 39 jewels | -Torque Return System

-Dual-Spring Barrel -Power reserve indicator |

| Automatic Spring Drive 3-Day Chronograph GMT Caliber 9R96 (Automatic with manual winding) |

±10 seconds per month (±0.5 second per day) | Approximately 72 hours | 50 jewels | -Power reserve indicator

-Dual time function with 24-hour hand -Quick correction function of time difference adjusting to a calendar -Stopwatch function |

| Automatic Spring Drive 3-Day Chronograph GMT Caliber 9R86 (Automatic with manual winding) |

±15 seconds per month (±1 second per day) | Approximately 72 hours | 50 jewels | -Power reserve indicator

-Dual time function with 24-hour hand -Quick correction function of time difference adjusting to a calendar -Stopwatch function |

| Automatic Spring Drive 3-Day GMT Caliber 9R66 (Automatic with manual winding) |

±15 seconds per month (±1 second per day) | Approximately 72 hours | 30 jewels | -Power reserve indicator

-Dual time function with 24-hour hand -Quick correction function of time difference adjusting to a calendar |

| Automatic Spring Drive 3-Day Caliber 9R65 (Automatic with manual winding) |

±15 seconds per month (±1 second per day) | Approximately 72 hours | 30 jewels | -Power reserve indicator

-Date display |

| Automatic Spring Drive 3-Day GMT Caliber 9R16 (Automatic with manual winding) |

±10 seconds per month (±0.5 second per day) | Approximately 72 hours | 30 jewels | -Power reserve indicator

-Dual time function with 24-hour hand -Quick correction function of time difference adjusting to a calendar |

| Manual-winding Spring Drive Caliber 9R31 (Manual winding) |

±15 seconds per month (±1 second per day) | Approximately 72 hours | 30 jewels | -Dual-Spring Barrel

-Power reserve indicator |

| Automatic Spring Drive 3-Day Caliber 9R15 (Automatic with manual winding) |

±10 seconds per month (±0.5 second per day) | Approximately 72 hours | 30 jewels | -Power reserve indicator |