9F

Quartz

Caliber 9F is an exclusive Grand Seiko quartz movement born in 1993. It is manufactured and assembled into complete timepieces at the Shinshu Watch Studio, located in Shiojiri, Nagano Prefecture.

Precision and longevity are the very essence of the ideal timepiece and have always been central to the ideals of Grand Seiko. Caliber 9F was designed to bring these attributes to the quartz watch, and it set a new standard for quartz in every aspect of its performance.

- Torque comparable to that of a mechanical movement makes the long and wide hands of Grand Seiko possible.

- The mechanism moves the hands smoothly.

- The Instant Date Change Mechanism advances the date display in the blink of an eye.

- The sealed structure improves the retention of the lubricating oils and prevents any dust from entering the movement when the battery is changed.

Caliber 9F redefines the quartz watch, delivering higher performance and greater durability. It is a quartz movement that truly merits the name Grand Seiko.

Mechanism

A quartz movement depends on a battery as its power source. The battery sends electricity to a quartz oscillator, which vibrates at precisely 32,768 times per second. An integrated circuit (IC) detects these vibrations and sends out an accurate time signal every second to the step motor. The step motor activates in accordance with this time signal, accurately rotating a series of gears and the watch hands.

Moving Grand Seiko’s broad hands with the Twin Pulse Control Motor

Unable to match the high torque of mechanical watches, quartz watches generally make use of lighter and thinner watch hands. Grand Seiko quartz models defy this limitation, and the hands have the same length and breadth as seen on every Grand Seiko mechanical watch. The 9F quartz movement makes this possible through its Twin Pulse Control Motor, a system capable of turning longer and heavier hands while preserving battery power.

In a normal quartz movement, the seconds hand moves in a single step from one second to the next. In the 9F quartz movement, the seconds hand instead makes two consecutive steps per second, triggered by two successive pulse signals. Increasing the number of pulse signals augments the output torque from the rotor, enabling the use of heavier hour, minute, and seconds hands. This two-step process is undetectable by the naked eye and appears as a single one-second step.

Independent Axis Structure for smooth hand movement

Inadvertent interference between the hour or minute hands and the seconds hand can occur during time adjustments, causing slight shaking in the thinner seconds hand. Because even the slightest shudder is incompatible with the standards of Grand Seiko, engineers developed a solution known as the Independent Axis Structure to prevent this problem.

A watch’s seconds hand travels around the dial 1,440 times every day while the minute hand completes 24 revolutions. Precise time can only be correctly displayed if there is no interference between these rotating parts.

In the 9F quartz movement, the axis of each hand is allowed to move independently, preventing the hands from brushing each other, eliminating twitching when the time is adjusted, and facilitating smooth and precise movement.

Precise movement of the seconds hand with the Backlash Auto-Adjust Mechanism

Watch hands are driven by a series of gears, and there is always a certain amount of play, or backlash, between the teeth that engage each wheel with the next. Although this backlash allows the gears to rotate smoothly, it is also responsible for the slight shuddering of the seconds hand, an imprecision unacceptable to Grand Seiko designers.

To address this, a unique method to enable the precise movement of the seconds hand, known as the Backlash Auto-Adjust Mechanism, was developed. The mechanism makes use of a hairspring, a core component of mechanical watches. By utilizing the slight spring power afforded by the hairspring, the faint shuddering of the seconds hand can be stabilized so that the seconds hand advances precisely and with no shudder.

Precise time adjustment

The movement of the crown is another unique facet of the 9F quartz movement.

In standard quartz watches, one full rotation of the crown moves the minute hand the equivalent of 60 minutes. In Caliber 9F, one full rotation of the crown moves the minute hand just 20 minutes, making it possible to adjust the time with greater precision.

Changing the date display in the blink of an eye

The 9F quartz movement utilizes a cam and lever in conjunction with the date indicator driving wheel as part of a feature known as the Instant Date Change Mechanism.

Through this mechanism, the date indicator driving wheel builds tension in the lever spring as it rotates, eventually releasing the stored energy when it reaches the location of the cam and driving the calendar wheel forward in the blink of an eye.

The task of aligning the Instant Date Change Mechanism to occur precisely at midnight falls upon Grand Seiko’s skilled craftspeople, who painstakingly set the mechanism by hand. In order to ensure that there is no situation in which the change occurs prematurely, the mechanism is set to activate within five minutes of midnight.

Regulation switching for precision adjustments during after-sales service

While mechanical watches possess a mechanism for fine-tuning precision, these controls are impossible in most quartz watches.

The 9F quartz movement, however, features a regulation switch that makes such precision control possible. If, because of environmental conditions or other factors, a Caliber 9F watch ever becomes too fast or slow, the switch can be used to correct for such divergences during after-sales service. Owners can enjoy the high precision of their watch for many years, even if it is worn in unusually high or low temperatures or other conditions. Given the high accuracy of the 9F quartz movement, ±10 seconds a year, most will never need to know this adjustment function even exists.

A protective shield construction and a unique bearing structure

Grand Seiko developed its protective shield construction, which prevents dust from entering the gear train of the movement when the battery is changed. This minimizes the risk of harm when the case is opened for battery changes, which every quartz movement requires. Also, a unique bearing assembly structure ensures that the rotor, the heart of the quartz movement, is encased in a highly airtight environment so that the lubricating oil reserve for the step motor pivot is sealed off from the air, extending the life of the oil.

To achieve higher precision

The 3-month aging process for quartz oscillators

The accuracy of a quartz watch depends on whether the quartz oscillator can maintain a precise rate of 32,768 oscillations per second.

Despite the overall regularity of this oscillation, each quartz oscillator has different performance characteristics, with some unable to maintain stable performance during the course of long use and changes in the environment. Other oscillators may perform with high precision at first, but undergo changes in their oscillation over the years, leading to inaccuracy.

As part of the process, quartz oscillators made in-house are first 'aged' for three months, during which they are subjected to certain voltages of electricity so that their characteristics stabilize. Only then are they tested and selected, and only quartz oscillators that meet strict standards are used in the 9F quartz movement.

Temperature monitoring 540 times a day

Quartz oscillators are susceptible to temperature changes.

The rate of 32,768 oscillations per second fluctuates with changes in ambient temperature.

To solve this problem, information on the individual characteristics of an oscillator is stored beforehand in the IC. By matching each oscillator with its own individually set IC in this way, 9F movements operate perfectly.

The temperature inside the watch is also measured 540 times a day. The temperature data is transferred to and processed by the IC, which compensates for any deviation that would be detrimental to preserving high accuracy.

A quartz movement crafted by hand

While the majority of the world's quartz movements are products of automatic assembly, Grand Seiko's Caliber 9F is assembled entirely by hand. Two expert craftspeople combine their individual talents to ensure the high quality standard of each Grand Seiko 9F movement, with one assembling the date indicator and the other the rest of the movement.

Once the movement is assembled, the dial, indexes and hands are attached, and the entire movement is cased. Attaching the watch hands is perhaps one of the most delicate and precise procedures, requiring the supreme skill of an experienced craftsperson.

The hour and minute hands are stacked in parallel within a space of just 2mm and fixed in place with the movement axis by frictional force. Only an expert in adjustment can ensure that all hands, a mere 0.2mm apart, operate smoothly without colliding with one another as they rotate.

In order to ensure that no scratch or blemish occurs on the hands during assembly, the Grand Seiko craftspeople polish the tips of their pincers several times every day. This is just one example of the painstaking detail involved in the creation of every Caliber 9F watch. It is this craftsmanship and skill that guarantees the quality, performance, and beauty of Grand Seiko quartz watches.

9F Quartz Models

9F Quartz Movement

Movement Comparison

| Movement | Accuracy | Battery life | Features |

|---|---|---|---|

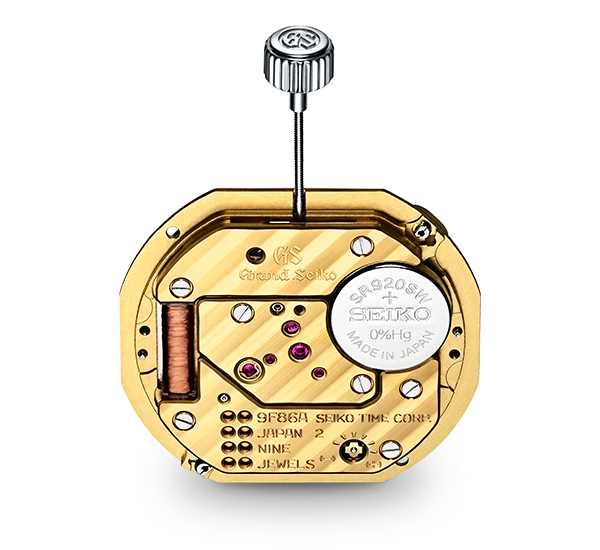

| A Model Featuring a Date Display with GMT Function Caliber 9F86 |

±10 seconds per year | Approximately 3 years | -Instant date change mechanism

-Dual time function with 24-hour hand -Quick correction function of time difference adjusting to a calendar |

| A Model Featuring a Date Display Caliber 9F85 |

±10 seconds per year | Approximately 3 years | -Instant date change mechanism

-Quick correction function of time difference adjusting to a calendar |

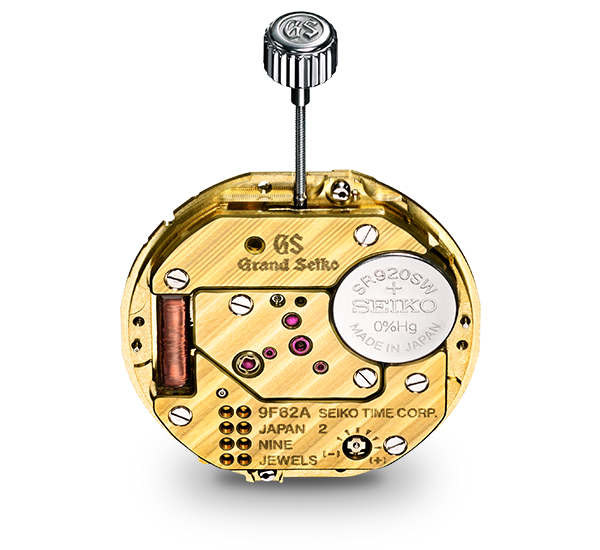

| A Model Featuring a Date Display Caliber 9F62 |

±10 seconds per year | Approximately 3 years | -Instant date change mechanism |

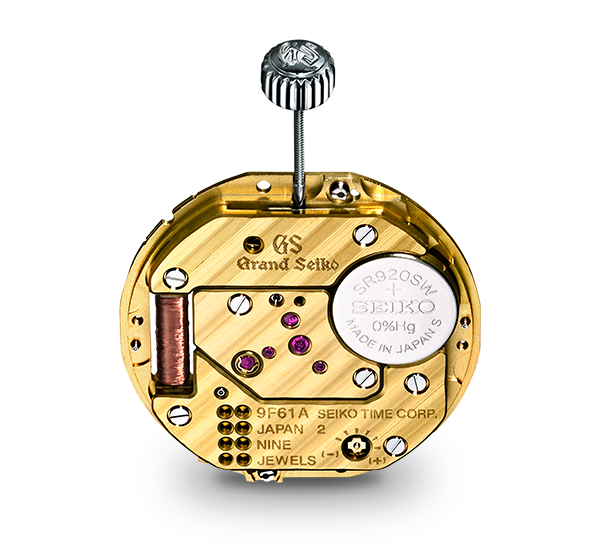

| A Model Featuring without a Date Display Caliber 9F61 |

±10 seconds per year | Approximately 3 years | - |