The magic of the mainspring

that rewinds as it unwinds.

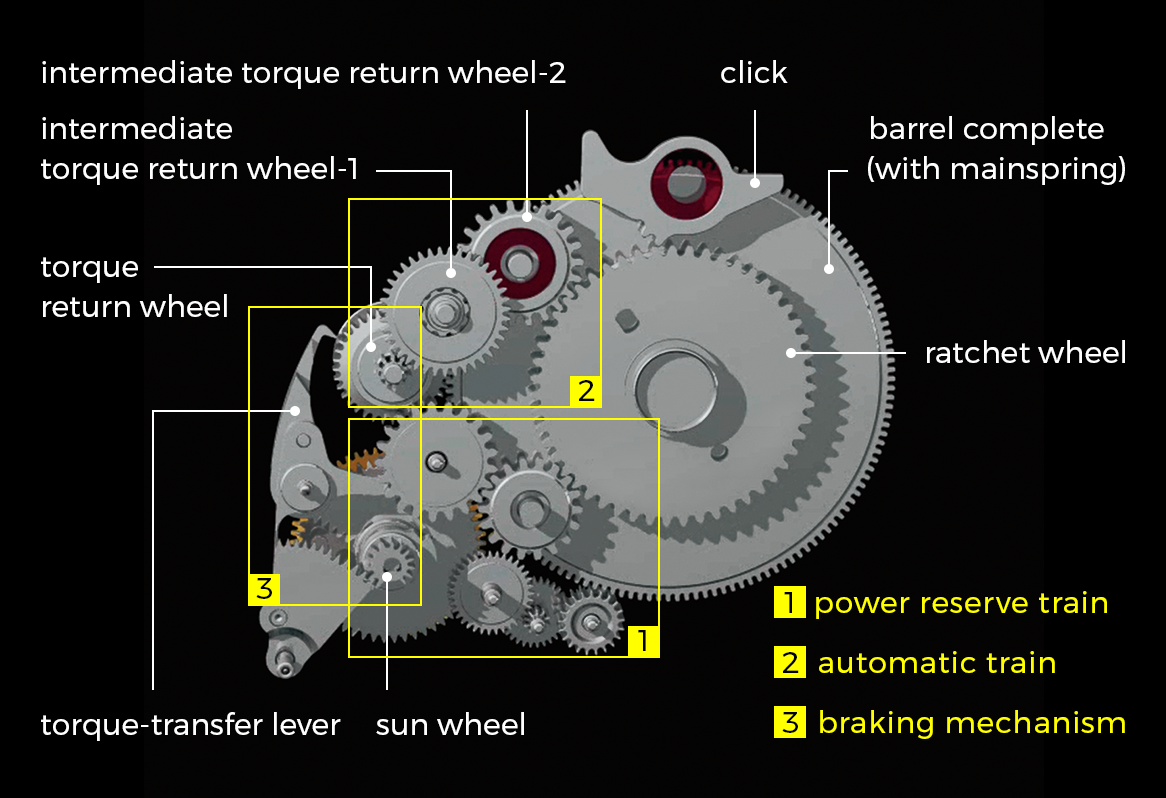

Takahashi had invented the Torque Return System in 2008 and he now modified it for Caliber 9R02. For some 48 hours after the mainspring has been fully wound, about 30 percent of the power generated by the unwinding of the mainspring, which has no effect on the watch’s performance, is used to rewind the mainspring. Thanks to this mechanism and the Dual Spring Barrel, Caliber 9R02 achieves a power reserve of 84 hours.

Takahashi says that this innovative mechanism first appeared in his head as a diagram. After working out the details and producing a prototype, he was able to confirm that it worked just as he had anticipated. Once he knew that the concept was sound, he worked to achieve the fullest possible extension to the power reserve through the reduction of friction. The result was impressive; an additional twelve hours’ reserve was achieved.

The striking beauty of

hand polished edges

The shafts of the gears that move the watch hands are held in place by the main plate on one side and the bridge on the other. In the slight space between the main plate and the bridge, several hundred delicate parts work in unison to store or release power. In Caliber 9R02, the large bridge is first mirror polished and then finished with a fine hairline pattern. This is, of course, not the only work done by hand by the expert craftsmen in charge of the finishing. Polishing the edge of the bridge is done by using the wood of a mountain tree to create a mirror finish on the sharply angled surface. The outer edges of the screw holes and jewels that receive the gear shafts are also polished to the same mirror-like finish. The quiet elegance of the hairline polish and the brilliance of the mirrored surfaces speak volumes for the high level of the craftsmanship that is involved in every detail, visible and hidden within the movement alike.