Spring Drive 5 Days

Caliber 9RA2

At the birthplace of Spring Drive, the Shinshu Watch Studio, dedicated craftsmen and women meticulously assemble timepieces by hand part by part, from the case, dial, hands and indexes to all other components. At every step of the movement creation process, from development and design to manufacture, assembly, and adjustment, talented and expert craftsmen and women strive for the highest possible standards and maintain their complete dedication to the constant enhancement of their skills. Caliber 9RA2 is the Spring Drive movement that best embodies these skills and their passion.

Caliber 9RA2 has an accuracy rate of ±10 seconds per month and utilizes the Offset Magic Lever to reduce the movement’s thickness by 0.8mm. By moving the position of the crown further back, the watch’s center of gravity is lowered and a perfect fit on the wrist results. The Dual-size Barrels are of differing sizes and arranged to allow for expanded capacity while conserving space. This achieves a 120 hour power reserve. The One-piece Center Bridge guarantees the movement’s strength, durability and shock resistance. Together, these innovative technologies define the next-generation Spring Drive movement, Caliber 9RA2.

Specifications

| Winding mechanism | Automatic with manual winding |

|---|---|

| Accuracy | ±10 seconds per month (±0.5 second per day) |

| Power reserve | Approximately 120 hours (5 days) |

| Number of jewels | 38 jewels |

| Features | -Offset Magic Lever

-Dual-size Barrels -One-piece Center Bridge -Power reserve indicator |

Caliber 9RA2 achieves a high accuracy of ± 10 seconds per month in large part by using a high precision Spring Drive package IC, which is a vacuum-sealed package consisting of a carefully selected crystal oscillator aged for three months and an IC that is powered by an extremely small electric current. The oscillation of a crystal oscillator is susceptible to temperature fluctuations, so Caliber 9RA2 utilizes a temperature sensor located within its special silicon-on-insulator IC (SOI-IC) to collect temperature data 540 times daily, determine the influence of temperature changes within the IC and compensate for variations in the oscillator’s performance. Furthermore, placing both the crystal oscillator and the IC within a single, vacuum-sealed package eliminates temperature differences between the IC and the crystal oscillator, allowing for highly precise temperature adjustments. Installing all wiring connecting the crystal oscillator with the IC within the vacuum-sealed package also prevents changes in humidity from influencing the movement in addition to the shielding the movement from the influence of static electricity and light.

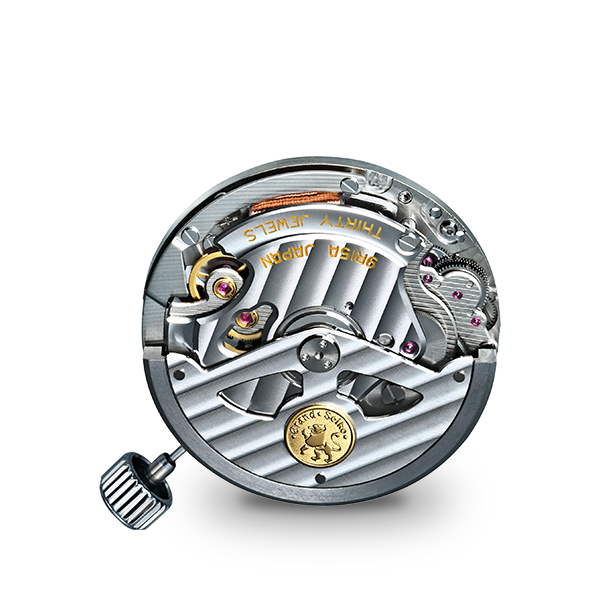

The exterior of the movement has a beauty that is uniquely Japanese and is inspired by the natural environment of the studio where it is made. The jewels echo the glittering stars that sparkle especially brightly during the early days of winter above the surrounding mountains and the delicate texture of the movement’s surfaces reflect the frost that winter brings to the trees.

A Slim Movement that allows the Watch to sit Comfortably

Caliber 9RA2 is 0.8mm thinner than Caliber 9R6 series. The slimming down of the components began with the oscillating weight, and the overall design reduced the distance from the bottom of the movement to the center of the crown from 4.2mm to 3.4mm. By moving the crown as far back as possible, the center of gravity of the watch is moved further down, achieving a comfortable and natural fit.

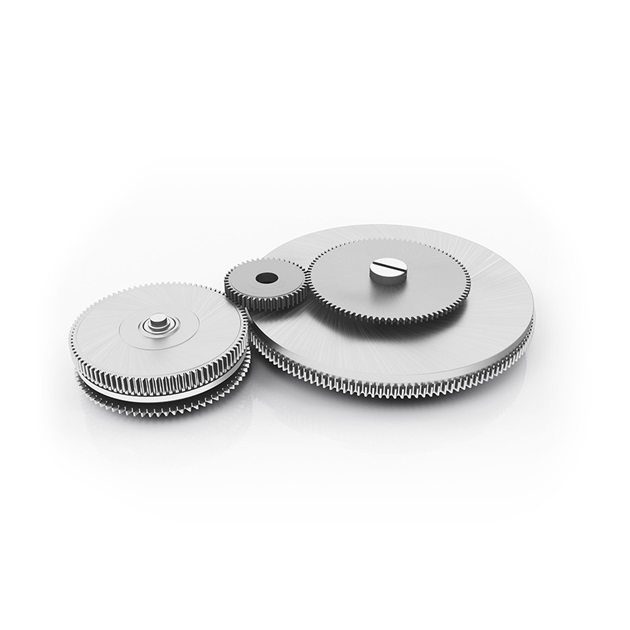

Achieving Greater Winding Efficiency and a Slimmer Movement, “The Offset Magic Lever”

Caliber 9RA2 uses the newly developed Magic Lever with crank wheel, which is offset from the center of the movement to achieve a slimmer size. The magic lever with crank wheel was made in the Shinshu Watch Studio using original cutting techniques, and it allowed for the new magic lever structure to minimize the load of the crank wheel. Furthermore, relocating the transmission wheel allowed the Offset Magic Lever to further reduce the movement’s size while simultaneously improving its winding efficiency.

Achieving the 120 Hour Power Reserve, “The Dual-size Barrels”

Caliber 9RA2 utilizes this mechanism together with a revised wheel train gear ratio to maintain the high torque achieved in Caliber 9R6 while simultaneously achieving a 120 hour power reserve. Inserting two barrels of the same size would have resulted in dead space, so a design was made with two barrels of differing sizes to utilize the limited space without any waste. Although barrels experience fluctuations in the transmission efficiency of kinetic energy based on their size, improvements to the Caliber 9RA2’s two barrels were made to ensure they would transmit energy from the mainspring at the same efficiency, resulting in the achievement of equal winding and unwinding.

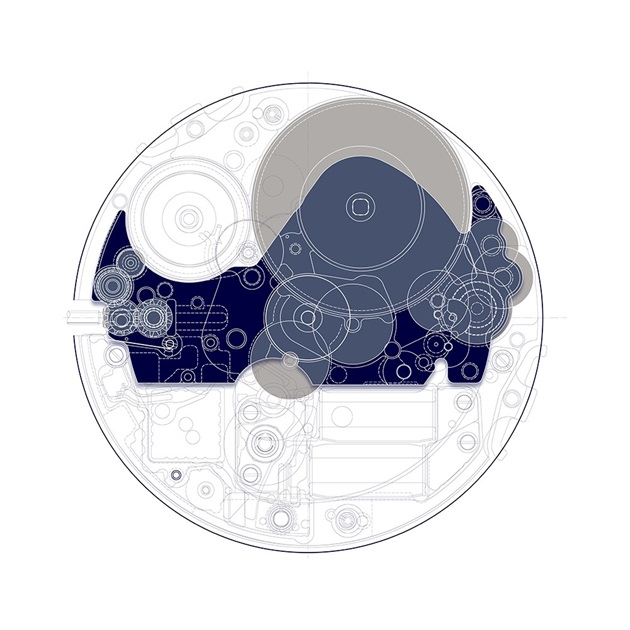

Achieving Significantly Higher Durability and Improved Transmission Efficiency, “The One-piece Center Bridge”

Caliber 9RA2 features a bridge design that combines the previously separate barrel bridge, center wheel bridge, and winding stem cock into a single “One-piece Center Bridge” that forms the central pillar of the movement.

This structure within Caliber 9RA2 reinforces the main plate at 3:00 and 9:00 and, by making it possible to contain most of the gear train within the structure, the movement overall enjoys significantly better strength, durability and shock resistance. Combining three previously separate components into a single piece also simplifies stocking and assembly in addition to greatly contributing to the improvement of the transmission ratio between the gears.

The Movement’s Finishing Reflects the Natural Beauty of Shinshu.

The exterior of Caliber 9RA2 is meticulously finished and reflects the natural beauty of its birthplace, in Shinshu Nagano Prefecture. The design itself draws inspiration from the gentle frost that covers the trees in the early winter and the starry sky visible from between their branches. Caliber 9RA2’s bridge design represents the frost and is finished with a neutral-toned sandblast coating that achieves a calm but elegant radiance. The ridgelines and edges of the bridges as well as the screws are finished with cut diamonds that represent the twinkling stars of the night sky.

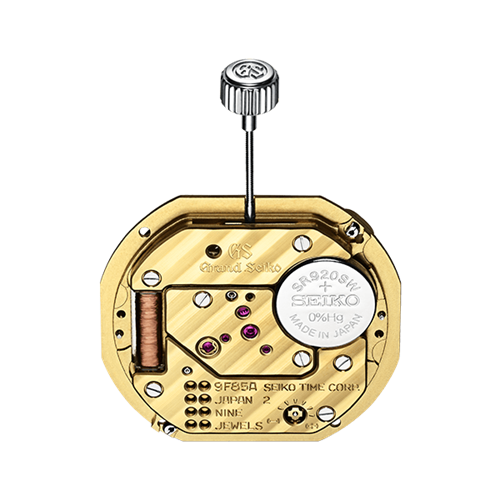

What makes 9R Spring Drive special?

Spring Drive, one of the great innovations in modern watch making history, regulates a spring-driven movement with state-of-the-art electronic technology that functions without batteries or other external power source. Its sole power source is a mainspring, which drives a series of gears. A rotor, connected to the end of these gears, generates a small electrical charge that activates an electronic circuit and quartz oscillator. Its accuracy is unprecedented for a watch wound by a mainspring. The development of the 9R Spring Drive movement was possible only because Grand Seiko is one of the few manufacturers with expertise in both mechanical and electronic watches.